Why Turbo Compounding May Be the Next Big Thing in Powertrains

The technology isn't new - the aerospace industry introduced the concept in the 1940s - but an article in Car and Driver says it could be "the next big thing in energy recovery" for automotive engines.

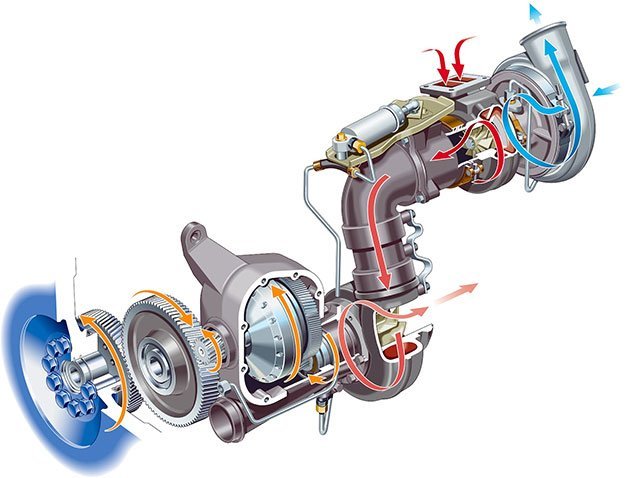

Turbo compounding is a way to take advantage of wasted exhaust gasses to provide more power to the engine. In the cutaway above, the compressor in the upper right (blue arrows) is powered by the turbine wheel to its left (red arrows) to send boosted intake air to the engine. The turbine, however, is also sending exhaust gas down the plumbing to its left, where another turbine connected to a shaft drives a set of gears, essentially a high-ration transmission ultimately connected to the crankshaft in the lower left.

Bowman, which engineers electrical compounding systems for power generation and heavy vehicle sectors, says its solution can increase efficiency by to seven percent with no negative impact. Mechanical compounding is said to supply gains of around five percent, but can have a negative impact depending on engine load.

Engine maker Detroit Diesel won the Truck Writers of North American Technical Achievement Award for its DD15 engine that uses mechanical compounding, and Scania and Volvo also use the tech for their truck engines. When it comes to automaker implementation, we might be looking at Formula One engine makers first: the new 1.6-liter turbo V6s use electrical compounding to run the MGU-H motor/generator to power a battery that provides extra boost during a lap.

Related News